SNS MGP seriyali uch rodli pnevmatik ixcham hidoyat havo silindrli magnitli

Buyurtma kodi

| Teshik hajmi (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | |

| Aktyorlik rejimi | Tozalangan havo | ||||||||||

| Ishchi ommaviy axborot vositalari | Ikki tomonlama harakat | ||||||||||

| Maksimal ish bosimi | 1.0Mpa | ||||||||||

| Min.Ish bosimi | 0,12Mpa | 0.1Mpa | |||||||||

| Fluid harorati | -10 ~ + 60 ℃ (muzlash yo'q) | ||||||||||

| Piston tezligi | 50~1000 mm/s | ||||||||||

| Buferlash rejimi | Ikkala uchi ham kauchuk buferlash | ||||||||||

| Zarbaga chidamlilik (mm) | 0+1,5 mm | ||||||||||

| Moylash | Kerak emas | ||||||||||

| Rulman turi | Sürgülü rulman / rulmanli rulman | ||||||||||

| Aylanmaydigan aniqlik | Slayd podshipnik | ±0,08° | ±0,07° | ±0,06° | ±0,05° | ±0,04° | |||||

| Bilyali rulman | ±0,10° | ±0,09° | ±0,08° | ±0,06° | ±0,05° | ||||||

| Port hajmi | M5X0.8 | 1/8 | 1/4 | 3/8 | |||||||

| Tana materiali | Alyuminiy qotishmasi | ||||||||||

Qon tomir

| Teshik hajmi (mm) | Standart zarba (mm) |

| 12 | 10 20 30 40 50 75 100 125 150 175 200 |

| 16 | 10 20 30 40 50 75 100 125 150 175 200 |

| 20 | 20 30 40 50 75 100 125 150 175 200 |

| 25 | 20 30 40 50 75 100 125 150 175 200 |

| 32 | 25 50 75 100 125 150 175 200 250 300 |

| 40 | 25 50 75 100 125 150 175 200 250 300 |

| 50 | 25 50 75 100 125 150 175 200 250 300 |

| 63 | 25 50 75 100 125 150 175 200 250 300 |

Sensorli kalitni tanlash

| Rejim/Teshik hajmi | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Sensorni almashtirish | D-Z73 | |||||||||

Hajmi

MG PM, MG PL, MG PA umumiy o'lchamlari (mm)

| Teshik hajmi (mm) | Standart zarba (mm) | B | C | DA | FA | FB | G | GA | GB | H | HA | J | K | L | MM | ML | NN | OA | OB | OL | Nil | TN | TF |

| 12 | 10,20,30,40,50,75,100 125,150,175,200,250 | 42 | 29 | 6 | 7 | 6 | 26 | 10 | 7 | 58 | M4 | 13 | 13 | 18 | M4x0,7 | 10 | M4x0,7 | 4.3 | 8 | 4.5 | M5x0,8 | - | - |

| 16 | 46 | 33 | 8 | 7 | 6 | 30 | 10.5 | 7.5 | 64 | M4 | 15 | 15 | 22 | M5x0,8 | 12 | M5x0,8 | 4.3 | 8 | 4.5 | M5x0,8 | - | - | |

| 20 | 20,30,40,50,75,100,125,150 175,200,250,300,350,400 | 53 | 37 | 10 | 8 | 8 | 36 | 11.5 | 9 | 83 | M5 | 18 | 18 | 24 | M5x0,8 | 13 | M5x0,8 | 5.4 | 9.5 | 5.5 | Rc1/8 | NPT1/8 | G1/8 |

| 25 | 53.5 | 37.5 | 10 | 9 | 7 | 42 | 11.5 | 10 | 93 | M5 | 21 | 21 | 30 | M6x1.0 | 15 | M6x1.0 | 5.4 | 9.5 | 5.5 | Rc1/8 | NPT1/8 | G1/8 |

| Teshik hajmi (mm) | PA | PB | PW | Q | R | S | T | U | VA | VB | WA | WB | X | XA | XB | YY | YL | Z | ||||||||

| st≤30 | st>30 st≤100 | st>100 st≤200 | st>200 st≤300 | st>300 | st≤30 | st>30 st≤100 | st>100 st≤200 | st>200 st≤300 | st>300 | |||||||||||||||||

| 12 | 13 | 8 | 18 | 14 | 48 | 22 | 56 | 41 | 50 | 37 | 20 | 40 | 110 | 200 | - | 15 | 25 | 60 | 105 | - | 23 | 3 | 3.5 | M5x0,8 | 10 | 5 |

| 16 | 14.5 | 10 | 19 | 16 | 54 | 25 | 62 | 46 | 56 | 38 | 24 | 44 | 110 | 200 | - | 17 | 27 | 60 | 105 | - | 24 | 3 | 3.5 | M5x0,8 | 10 | 5 |

| 20 | 13 5 | 15.5 | 25 | 18 | 70 | 30 | 81 | 54 | 72 | 44 | 24 | 44 | 120 | 200 | 300 | 29 | 39 | 77 | 117 | 167 | 28 | 3 | 3.5 | M6x1.0 | 12 | 17 |

| 25 | 12.5 | 13.5 | 30 | 26 | 78 | 38 | 91 | 61 | 82 | 50 | 24 | 44 | 120 | 200 | 300 | 29 | 39 | 77 | 117 | 167 | 34 | 4 | 4.5 | M6x1.0 | 12 | 17 |

MGPM (slaydli rulman)/A, DB, E o'lchamlari (mm)

| Teshik hajmi (mm) | A | DB | E | ||||||

| st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | ||

| 12 | 42 | 60.5 | 82.5 | 82.5 | 8 | 0 | 18.5 | 40.5 | 40.5 |

| 16 | 46 | 64.5 | 92.5 | 92.5 | 10 | 0 | 18.5 | 46.5 | 46.5 |

| 20 | 53 | 77.5 | 77.5 | 110 | 12 | 0 | 24.5 | 24.4 | 57 |

| 25 | 53.5 | 77.5 | 77.5 | 109.5 | 16 | 0 | 24 | 24 | 56 |

MGPL (Bolli rulmanlar) MGPA (Yuqori aniqlikdagi sharli rulmanlar)/A, DB, E o'lchamlari (mm)

| Teshik hajmi (mm) | A | DB | E | ||||||

| st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | ||

| 12 | 43 | 55 | 84.5 | 84.5 | 6 | 1 | 13 | 42.5 | 42.5 |

| 16 | 49 | 65 | 94.5 | 94.5 | 8 | 3 | 19 | 48.5 | 48.5 |

| 20 | 59 | 76 | 100 | 117.5 | 10 | 6 | 23 | 47 | 64.5 |

| 25 | 65.5 | 81.5 | 100.5 | 117.5 | 13 | 12 | 28 | 47 | 64 |

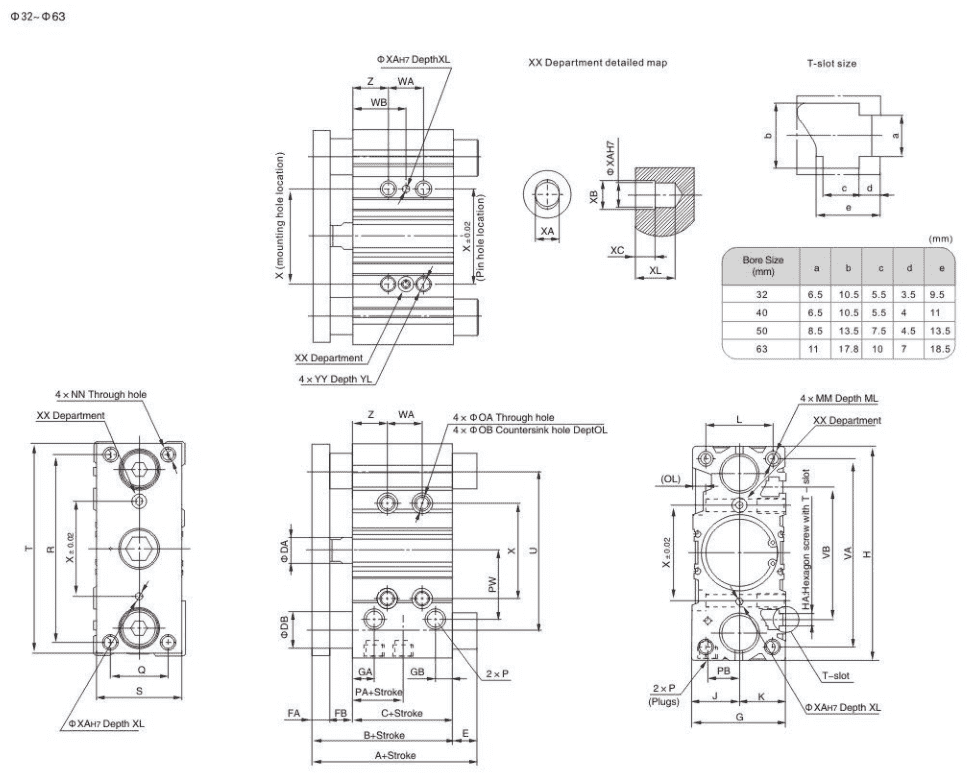

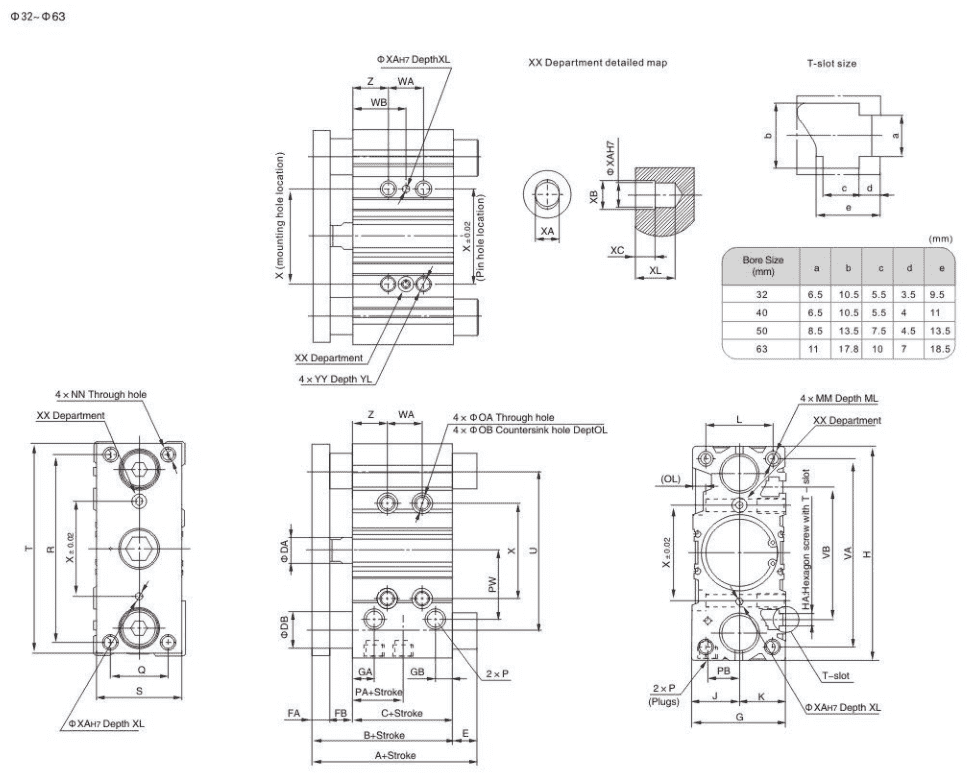

Hajmi

MGPM, MGPL, MGPA CommonDinensions (mm)

| Teshik hajmi (mm) | Standart zarba (mm) | B | C | DA | FA | FB | G | GA | GB | H | HA | J | K | L | MM | ML | NN | OA | OB | OL | Nil | TN | TF |

| 32 | 25,50,75,100,125,150 175,200,250,300,350,400 | 59.5 | 37.5 | 14 | 10 | 12 | 48 | 12 | 9 | 112 | M6 | 24 | 24 | 34 | M8x1,25 | 20 | M8x1,25 | 6.7 | 11 | 7.5 | Rc1/8 | NPT1/8 | G1/8 |

| 40 | 66 | 44 | 14 | 10 | 12 | 54 | 15 | 12 | 120 | M6 | 27 | 27 | 40 | M8x1,25 | 20 | M8x1,25 | 6.7 | 11 | 7.5 | Rc1/8 | NPT1/8 | G1/8 | |

| 50 | 72 | 44 | 18 | 12 | 16 | 64 | 15 | 12 | 148 | M8 | 32 | 32 | 46 | M10x1,5 | 22 | M10x1,5 | 8.6 | 14 | 9 | Rc1/4 | NPT1/4 | G1/4 | |

| 63 | 77 | 49 | 18 | 12 | 16 | 78 | 15.5 | 13.5 | 162 | M10 | 39 | 39 | 58 | M10x1,5 | 22 | M10x1,5 | 8.6 | - | 9 | Rc1/4 | NPT1/4 | G1/4 |

| Teshik hajmi (mm) | PA | PB | PW | Q | R | S | T | U | VE | VB | WA | WB | X | XA | XB | XC | XL | YY | YL | Z | ||||||||

| st≤25 | st>25 st≤100 | st>100 st≤200 | st>200 st≤300 | st>300 | st≤25 | st>25 st≤100 | st>100 st≤200 | st>200 st≤300 | st>300 | |||||||||||||||||||

| 32 | 6.5 | 16 | 35.5 | 30 | 96 | 44 | 110 | 78 | 98 | 63 | 24 | 48 | 124 | 200 | 300 | 33 | 45 | 83 | 121 | 171 | 42 | 4 | 4.5 | 3 | 6 | M8x1,25 | 16 | 21 |

| 40 | 13 | 18 | 39.5 | 30 | 104 | 44 | 118 | 86 | 106 | 72 | 24 | 48 | 124 | 200 | 300 | 34 | 46 | 84 | 122 | 172 | 50 | 4 | 4.5 | 3 | 6 | M8x1,25 | 16 | 22 |

| 50 | 9 | 21.5 | 47 | 40 | 130 | 60 | 146 | 110 | 130 | 92 | 24 | 48 | 124 | 200 | 300 | 36 | 48 | 86 | 124 | 174 | 66 | 5 | 6 | 4 | 8 | M10x1,5 | 20 | 24 |

| 63 | 13 | 28 | 58 | 50 | 130 | 70 | 158 | 124 | 142 | 110 | 28 | 52 | 128 | 200 | 300 | 38 | 50 | 88 | 124 | 174 | 80 | 5 | 6 | 4 | 8 | M10x1,5 | 20 | 24 |

MGPM (slaydli podshipnik)/A, DB, E o'lchamlari (mm)

| Teshik hajmi (mm) | A | DB | E | ||||

| st≤50 | st>50 st≤200 | st>200 | st≤50 | st>50 st≤200 | st>200 | ||

| 32 | 75 | 93.5 | 129.5 | 20 | 15.5 | 34 | 70 |

| 40 | 75 | 93.5 | 129.5 | 20 | 9 | 27.5 | 63.5 |

| 50 | 88.5 | 109.5 | 150.5 | 25 | 16.5 | 37.5 | 78.5 |

| 63 | 88.5 | 109.5 | 150.5 | 25 | 11.5 | 32.5 | 73.5 |

MGPL (Bolli rulmanlar) MGPA (Yuqori aniqlikdagi sharli rulmanlar)/A, DB, E o'lchamlari (mm)

| Teshik hajmi (mm) | A | DB | E | ||||||

| st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | st≤50 | st>50 st≤100 | st>100 st≤200 | st>200 | ||

| 32 | 79.5 | 96.5 | 116.5 | 138.5 | 16 | 20 | 37 | 57 | 79 |

| 40 | 79.5 | 96.5 | 116.5 | 138.5 | 16 | 13.5 | 30.5 | 50.5 | 72.5 |

| 50 | 91.5 | 112.5 | 132.5 | 159.5 | 20 | 19.5 | 40.5 | 60.5 | 87.5 |

| 63 | 91.5 | 112.5 | 132.5 | 159.5 | 20 | 14.5 | 35.5 | 55.5 | 82.5 |

Suyuqlik kuchaytirgich tsilindrining ishlash printsipi

Yog 'bosimi tsilindri va kuchaytiruvchi qurilmadan tashkil topgan havo va suyuqlik kuchaytiruvchi silindr, past havo bosimini qo'llaniladigan kesma kesishuv orqali o'nlab vaqtga yuqori bosimga o'tkazadi, kuchaytirgich moslamasida katta va kichik piston bo'lib, bu yuqori bosim yog 'bosimi tsilindriga etkazib beriladi, gidravlik qiladi. yuqori bosimni chiqarish uchun silindr.

Tavsiya etilgan operatsion tsikl